One-Stop Manufacturing

Solutions for your Brand

Our company specializes in contract manufacturing in India, producing Oral care, skin care, hair care, baby care, men grooming, Derma care, Essential Oils, Body Powders, Salon Range, Colour Cosmetics, Ayurvedic Care, and we use a batch manufacturing process to create our products. Batch manufacturing involves producing a specific quantity of a product in one batch or lot, which is then repeated to create the next batch.

The ability to produce flexible batch sizes is advantageous for us as it allows us to meet the specific demands of both large and small orders without wasting resources.

Custom made formulation for your product

Packaging Facility

Tubes

Bottles

Jars

Pouches

Containers

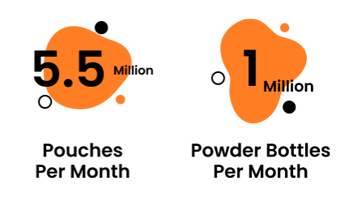

Filling Capacity

Modern State of Art Manufacturing Facility

- Adhering to the cGMP/ ISO standards of manufacturing.

- All Manufacturing And Filling areas maintained under class 1,00,000 (HEPA Filters) with kota flooring and kota corner covings.

- HEPA filters with inlet air filter at terminal – 0.3 micron and return air filter – 10 micron with controlled temp. and relative RH%.

- Separate man and material entry Air Locks for each manufacturing area as well as filling rooms.

- Separate manufacturing zone for non-classified products – Soaps and Talcum Powders

- Total Area of Premise – 60,000 sq.ft. (5600 Sq.m.)

Research, Development, Innovation

- We have in-house state of art laboratory for testing of raw materials, packaging materials, inprocess material and finished products.

- R&D facility is constructed under a Pharma Clean Room Partition with PVC flooring and covings.

- Lab has been zoned in to several separate departments according to the tests to be performed- Stability area, Instrument area, physio-chemical area, R&D pilot mixer area, and Q.C. staff area.

- In house Lab Scale manufacturing plant for all products, dedicated highly skilled staff for development of customized formulations for individual customers

- Lab is equipped with a pilot plant 5 kg (3 vessel system with vacuum) for pilot batch trials prior to commercial production.

- Our products undergo stability testing under controlled temperature and humidity for 1, 3, 6, and 12 months to ensure their quality and effectiveness.

Effluent Treatment Plant (ETP)

INNOVATORES

At Orchid Lifesciences, we believe in constantly pushing the boundaries of innovation and research to create superior cosmetic formulations. Our state-of-the-art R&D and testing facility is equipped with modern world-class equipment, allowing our team of highly experienced and dedicated chemists to stay ahead of the curve.

Our research and innovation-based approach helps us stay up to date with the latest trends and develop cutting-edge formulations for a wide range of contemporary Premium Cosmetics products and Organic Cosmetics products. We are committed to helping our customers cater to the demands of their ever-changing markets by providing them with innovative and high-quality formulations.