The cosmetic industry in India has seen tremendous growth, this is because of an increase in demand for a wide range of beauty & personal care products. A significant factor contributing to this growth is the rise of leading third party cosmetic manufacturers like Orchid Lifesciences. These manufacturers are also known as contract manufacturers or private label manufacturers. They offer comprehensive manufacturing services that allow brands to produce cosmetic products under their brand name without investing in any manufacturing or production facilities.

A cosmetic manufacturer in India like Orchid Lifesciences can provide a full spectrum of services starting from cosmetic product formulation & development to label design & packaging. These manufacturers cater to various segments which include skincare, hair care, personal care products, oral care, baby care, and even specialized Ayurvedic plus GMP-certified products. By utilizing third party manufacturing or contract manufacturing services brands can bring their range of products to market quickly.

Third party cosmetic manufacturing offers flexibility and scalability which makes it an attractive option for both established brands and new entrants in the market. These cosmetic manufacturers in India ensure high-quality production standards and often adhere to international certifications like GMP to guarantee product safety and efficacy. Additionally, private label cosmetic manufacturing enables brands to create unique and customized products such as skin care & hair care solutions tailored according to specific market needs.

In essence, collaborating with Orchid Lifesciences – leading third party cosmetic manufacturer in India allows brands to focus on their core competencies like marketing and brand building while leveraging the expertise of experienced manufacturers. This collaboration results in a diverse and innovative range of products that meet the evolving demands of the beauty and personal care industry.

Definition of Third Party Cosmetic Manufacturing

Third party manufacturer is a company or entity that manufactures beauty care & personal care products for other brands according to their convenience. Third party manufacturers like Orchid Lifesciences do not sell any personally labeled products but do provide private label services so all the customers who want their dream product to be branded by their name can easily do it. Only a few Third party manufacturers like Orchid Lifesciences can provide a cost-effective solution for brands to develop and expand their product lines without investing in their manufacturing facilities.

Best Third Party Cosmetic Manufacturers in India – Orchid Lifesciences

India is a democratic country with 141.72 Cr people with 141.72 crore different choices!! But when it comes to Third party manufacturers everyone looks up to Orchid Lifesciences without a doubt. They have worked hard to achieve this level of trust in third party manufacturing industry, Orchid Lifesciences has a facility set up spread over a huge area of 5600 sq.m equipped with ultra-modern state-of-the-art automated manufacturing & filling machinery which employs 150+ employees.

![]()

Orchid Lifesciences is certified by many reputed associations like WHO- GMP facility, ISO 22716 certified, DUNS registered, and GST Compliant and and is also approved by FDA ( Food and Drug Administration ). which makes them a popular choice not only in India but also in countries across the globe. This assures that each & every product Manufactured at Orchid Lifesciences is 100% safe to use and is effective as well.

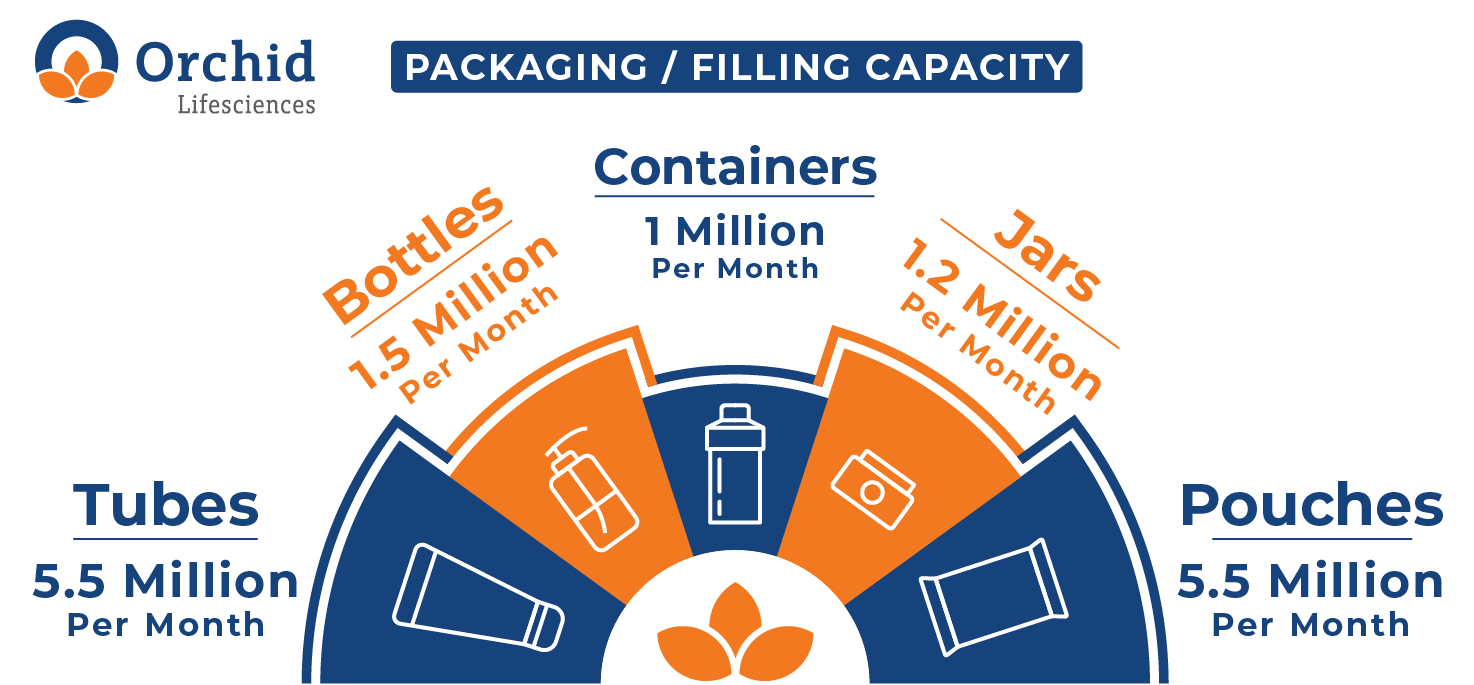

They now have manufacturing capabilities for catering to various batch sizes, ranging from 25 kgs to 2000 kgs per batch. Their filling capacity for tubes has expanded from 25 Lakh to 55 Lakh per month, Bottle filling capacity from 5 Lakh to 15 Lakh per month, and jars from 5 Lakh to 12 Lakh per month. They also introduced new pouch packaging machines with a filling capacity of 55 Lakh pouches per month.

They already have the best quality product by undertaking public demands and understanding their needs, Orchid Lifesciences added a range of ayurvedic products like herbal toothpaste, toothpaste with quality of neem extracts and many other essential oils as well as pure extracts. This is why clients and customers choose Orchid Lifesciences as their ultimate partner. Therefore, if you want your product to excel in the market in every niche connect with Orchid Lifesciences today!! What are you waiting for? All the details are given below just visit them 👇

Address:

Plot No. 68-72, Tribhuvan Industrial Estate, Road No.11, Nr. Kathwada GIDC, Kathwada, Ahmedabad, Gujarat-382430

Contact:

+91-8980815444

+91-9898026828

+91-9922840985

Email – marketing@orchidlifesciences.com

Website:

https://orchidlifesciences.com/

Importance of Orchid Lifesciences as a Third Party Cosmetic Manufacturer in India

1. Cost-Effectiveness

-

Reduced Investment

Brands can avoid the high costs of setting up and maintaining their manufacturing units. They can simply coordinate with leading cosmetic manufacturers like Orchid Lifesciences and get their ready-to-go privately labeled cosmetic products.

-

Economies of Scale

Third-party manufacturers often produce in large quantities to reduce cost per unit. This is beneficial for both customer & third party manufacturers because customers get huge quantities and manufacturers can save time as well as money.

2. Focus on Core Competencies

-

Brand Building

Companies can focus on marketing, sales, and brand development rather than manufacturing. The reason for collaborating with third-party manufacturers is not always money or manufacturing unit, some times people also connect with leading third party cosmetic manufacturers like Orchid Lifesciences to save time & effort invested in manufacturing products.

-

R&D

They can invest more in research & development to improve product offerings. Orchid Lifesciences is the topmost choice of every customer who wants their products to be manufactured in a safe environment and well-researched. To assure this Orchid Lifesciences have a specialized team of R&D with 40+ years of experience in the field. They check products at every stage of the process starting from manufacturing-packaging-delivering products.

3. Quality Assurance

-

Expertise

Among the multiple manufacturers in the market, Orchid Lifesciences stands out as the one with true expertise. People can accept this sentence because their team is full of smart & hard-working employees who carry more than 40 years of experience with them. All these people together help Orchid Lifesciences to achieve the top spot.

-

Certifications

Many manufacturers do not have the necessary certifications which assure adherence to quality standards. But on the other hand, Orchid Lifesciences is certified by many reputed associations like WHO- GMP facility, ISO 22716 certified, DUNS registered, and GST Compliant which makes them a popular choice not only in India but also in countries across the globe.

4. Flexibility and Scalability

-

Demand Fluctuations

Brands can scale production up or down based on market demand without worrying about the constraints of owning a manufacturing unit. Many companies across the globe rely on third party manufacturing companies like Orchid Lifesciences for manufacturing their precious cosmetic products because they know ,no other unit/company can stand when it comes to maintaining the highest possible quality at affordable prices.

-

Diverse Product Range

They can easily diversify their product lines as third party manufacturers often can produce a wide range of cosmetic products. Orchid Lifesciences not only delivers a wide range of cosmetic products but is also popular for third party Oral care, hair care, body care, skin care, derma care, men’s grooming products, baby care, and many more products.

5. Innovation and Customization

-

Access to New Technologies

Orchid Lifesciences as a Leading Third party cosmetic manufacturer often invests in the latest technologies and production methods to receive the best outcome possible. To ensure this they use advanced machinery in every step of production, so all the products manufactured at Orchid Lifesciences remain untouched, pure & safe to use.

-

Customization

We at Orchid Lifesciences offer customizable solutions tailored to specific brand requirements this allows us to deliver unique offers and high-quality cosmetic products. Here customers can select each & everything whether it is raw material, packet design, or private label, if customers are not able to make any selection then Orchid Lifesciences guides them to do so and select the best ingredients for their products. Orchid Lifesciences is not just a third party cosmetic manufacturer but like a family for their customers.

6. Risk Mitigation

-

Reduced Operational Risks

Outsourcing manufacturing mitigates risks associated with production issues, equipment failures, and workforce management.

-

Shared Responsibility

The responsibility for maintaining production standards and complying with regulations is shared. It means that when you collaborate with any cosmetic third party cosmetic manufacturer, it becomes very important to maintain all the standards and policies set by authorities on an international level. If you are collaborating with Orchid Lifesciences then we are always there to guide & support you even with guidelines but it’s your responsibility to follow them strictly.

7. Market Penetration

-

Local Expertise

Orchid Lifesciences as a proud Indian third party manufacturer they are able to understand local market dynamics, consumer preferences, and regulatory landscape. This allows brands to boost in the cosmetic industry.

-

Global Reach

Orchid Lifesciences produces for international markets and helps brands to expand their market globally. That is the reason why products manufactured by Orchid Lifesciences are not only loved by Indians but are also loved by many people in the world like Africa, South Asia, etc.

8. Sustainable Practices

-

Environmental Compliance

As Orchid Lifesciences is a leading third party cosmetic manufacturer we adhere to environmentally sustainable practices and help brands to align with eco-friendly initiatives. This is the reason why Orchid has already allotted a separate sector to recycle bio-waste generated while manufacturing cosmetic products.

-

Waste Management

Efficient waste management practices reduce environmental impact, promoting a positive brand image. To ensure this Orchid Lifesciences have installed ETP (Effluent Treatment Plant) and uses ingredients sourced from some of the trusted agencies. Along with this they ensure that every single ingredient is thoroughly checked and passed by their R&D experts for the best possible results.

Overview of the Cosmetic Industry in India

Indian Cosmetic Market was valued at USD 8.1 billion in 2023 and is projected to grow to USD 18.4 billion by 2032, with a compound annual growth rate (CAGR) of 3.2% during the forecast period from 2023 to 2032.

1. Market Size and Growth Trends

The expansion of e-commerce platforms has made cosmetics more accessible, while social media and beauty influencers continue to boost product demand. Key trends in the market include a growing preference for natural and organic products, an expanding male grooming segment, the introduction of innovative and technologically advanced products, and a rising demand for customized and personalized items. Additionally, there is a significant shift towards sustainable and eco-friendly products due to increasing consumer awareness about environmental impact.

2. Key Drivers of the Industry

Cosmetic manufacturing industry in India is driven by several key factors. Rising disposable incomes have increased spending on beauty products, while urbanization and changing lifestyles have heightened the focus on grooming. Growing awareness of personal hygiene, bolstered by marketing and social media, has boosted demand. E-commerce platforms have made cosmetics more accessible, increasing sales. Social media and beauty influencers shape consumer preferences and drive demand for new products. Manufacturers are expanding product lines to cater to diverse skin types, ages, and preferences, attracting a broader customer base. Technological advancements and innovations in skin care and beauty products, such as anti-aging and multifunctional items, have further spurred interest.

The demand for men’s grooming products is also rising as more men focus on personal care. Additionally, there is a significant shift towards natural and organic products due to health and environmental concerns. Lastly, growing awareness of sustainability and environmental impact is driving demand for eco-friendly packaging and cruelty-free products. These factors collectively drive the industry’s growth, shaping market trends and consumer behaviour in India.

Process Followed by Third Party Cosmetic Manufacturer in India

1. Product Conceptualization

1. Market Research

This involves understanding the market trends, customer preferences, and competitor products. Brands conduct surveys, focus on groups, and analyze market data to identify potential product ideas.

2. Idea Generation

Based on the research, brands brainstorm and generate ideas for new products. This could involve new product categories, improvements on existing products, or completely innovative concepts.

3. Concept Development

The chosen ideas are developed into detailed product concepts. This includes defining the target audience, unique selling points (USPs), product benefits, and preliminary design ideas.

4. Feasibility Analysis

A feasibility study is conducted to assess the technical, financial, and regulatory viability of the product concept. This includes cost estimation, potential return on investment (ROI), and compliance with cosmetic regulations.

2. Formulation and Development

1. Initial Formulation:

The brand works with the manufacturer’s R&D team to develop the initial formulation. This involves selecting ingredients, determining proportions, and creating a prototype.

2. Prototype Testing

The prototype is tested for various parameters such as texture, fragrance, stability, and performance. Feedback from these tests is used to refine the formulation.

3. Stability and Safety Testing

Extensive testing is conducted to ensure the product is stable over its intended shelf life and safe for use. This includes microbial testing, compatibility testing, and dermatological tests if necessary.

4. Regulatory Compliance

The formulation is reviewed to ensure it meets all regulatory requirements for the target market. This may involve checking permissible ingredient levels, labeling requirements, and safety assessments.

3. Sourcing of Raw Materials

1. Supplier Selection:

The manufacturer identifies and selects reliable suppliers for the raw materials needed for the product. This involves vetting suppliers for quality, reliability, and compliance with industry standards.

2. Quality Assurance:

Each batch of raw materials is tested for quality and consistency before being accepted for production. This ensures that the final product meets the desired standards.

3. Sustainability Considerations:

Increasingly, brands are looking for sustainable and ethically sourced raw materials. This includes sourcing organic ingredients, using fair trade suppliers, and minimizing environmental impact.

4. Manufacturing and Quality Control

1. Batch Production

The manufacturing process starts with the production of the cosmetic product in batches. This involves mixing, heating, and cooling processes as required by the formulation.

2. In-Process Quality Control

During manufacturing, quality control checks are performed at various stages to ensure the product meets the specified standards. This includes checking the consistency, pH, viscosity, and other critical parameters.

3. Final Product Testing

After production, the finished products undergo rigorous testing to ensure they are free from contaminants, have the correct composition, and perform as expected.

4. Compliance Documentation

Detailed records of the manufacturing process, quality checks, and compliance with regulatory standards are maintained. This documentation is crucial for traceability and audits.

5. Packaging and Labeling

1. Package Design

The brand and manufacturer collaborate to design packaging that is functional, attractive and aligns with the brand’s image. This includes selecting materials, colours, and graphics.

2. Labeling Requirements

Labels are designed to comply with regulatory requirements. They must include information such as ingredients, usage instructions, expiration date, batch number, and any required warnings or certifications.

3. Filling and Sealing

The product is filled into the packaging containers using automated machinery to ensure precision and efficiency. The containers are then sealed to maintain product integrity.

4. Quality Inspection

A final inspection is conducted to ensure that the packaging and labeling meet the required standards and that the product is correctly sealed and free from defects.

6. Distribution and Logistics

1. Logistics Planning

Effective logistics planning ensures that the finished products are delivered to the client or directly to the market in a timely and cost-effective manner. This includes coordinating transportation, warehousing, and inventory management.

2. Inventory Management

The manufacturer manages inventory levels to ensure that the right quantities of products are produced and available for distribution. This helps in meeting market demand and avoiding stock outs or overproduction.

3. Shipping and Handling

Products are carefully packed and shipped to their destination. This includes handling any special requirements for temperature control, fragility, or regulatory compliance for different regions.

4. Tracking and Monitoring

Advanced tracking systems are used to monitor the shipment’s progress and ensure timely delivery. Any issues during transit are promptly addressed to avoid delays.

5. After-Sales Support:

The manufacturer may offer after-sales support, including handling returns, addressing customer complaints, and providing technical assistance if needed.

Factors to Consider While Choosing a Third Party Manufacturer

1. Expertise and Experience

-

Industry Knowledge

A manufacturer’s expertise is reflected in their deep understanding of the cosmetic industry, including trends, regulations, and technological advancements. Experienced manufacturers are adept at anticipating and adapting to market changes.

-

Technical Skills

Proficient manufacturers have skilled R&D teams capable of developing innovative formulations and solving technical challenges. This includes expertise in ingredients, formulation techniques, and product stability.

-

Portfolio of Products

Reviewing the manufacturer’s portfolio can provide insight into their capabilities and experience with different types of cosmetic products, such as skin care, hair care, personal care, oral care, baby care, men’s grooming products and derma care items.

-

Past Projects

Experience with successful past projects, especially with well-known brands, can be a good indicator of a manufacturer’s ability to deliver high-quality products and meet client expectations.

2. Quality Standards and Certifications

-

Quality Control Processes

A reliable manufacturer should have stringent quality control processes in place at every stage of production, from raw material sourcing to final product testing. This ensures that the products meet the required quality standards consistently.

-

Certifications

Certifications from recognized bodies are a testament to a manufacturer’s commitment to quality. Common certifications include ISO (International Organization for Standardization), GMP (Good Manufacturing Practices) and others specific to cosmetics like COSMOS or ECOCERT for organic products.

-

Regulatory Compliance

Manufacturers must comply with local and international cosmetic regulations, such as the FDA (U.S. Food and Drug Administration) or the EU Cosmetics Regulation. This ensures that the products are safe, effective and properly labeled.

-

Testing and Documentation

Comprehensive testing for safety, efficacy, and stability is crucial. Detailed documentation of these tests provides transparency and traceability, which is essential for regulatory compliance and quality assurance.

3. Production Capacity and Flexibility

-

Production Scale

The manufacturer’s production capacity should align with the brand’s requirements, whether it’s for small-batch, medium-scale, or large-scale production. Assessing their facility size, equipment, and technology is important.

-

Flexibility

The ability to scale production up or down based on demand is a valuable trait. Flexible manufacturers can accommodate changes in order volume, new product launches, and seasonal fluctuations.

-

Lead Times

Short and reliable lead times are critical for timely market entry and meeting consumer demand. Manufacturers should have efficient processes to minimize delays.

-

Customization

A flexible manufacturer can offer customization options for formulations, packaging, and labeling, which is important for brands looking to differentiate their products in the market.

4. Cost and Pricing

-

Cost Structure

Understanding the manufacturer’s cost structure, including raw materials, labour, production, and overhead costs is essential. Transparent pricing helps in making informed decisions and avoiding hidden costs.

-

Competitive Pricing

The manufacturer should offer competitive pricing without compromising on quality. This involves balancing cost efficiency with high production standards.

-

Payment Terms

Favorable payment terms, such as flexible payment schedules or discounts for bulk orders, can help manage cash flow and budgeting.

-

Value for Money

Assessing the overall value provided by the manufacturer, including their expertise, quality standards, and additional services, helps in determining if the cost justifies the benefits received.

5. Reputation and Client Reviews

-

Industry Reputation:

A manufacturer’s reputation in the industry is a strong indicator of their reliability and performance. This can be assessed through industry awards, recognitions, and their standing in trade associations.

-

Client Testimonials:

Reviews and testimonials from current and past clients provide insight into the manufacturers strengths and weaknesses. Positive feedback on product quality, timeliness, and customer service is a good sign.

-

Case Studies

Detailed case studies of successful projects demonstrate the manufacturer’s capability to meet client expectations and deliver results. They highlight the manufacturer’s problem-solving skills and ability to manage complex projects.

-

References

Asking for references and directly contacting past clients can provide first-hand information on the manufacturer’s performance, reliability, and overall experience.

Conclusion

In conclusion, third party cosmetic manufacturing has become an integral part of the cosmetic industry in India, offering brands a reliable and efficient way to produce high-quality products. By partnering with a third party manufacturing company, brands can benefit from the expertise of leading private label cosmetic manufacturers and third party cosmetic manufacturers who excel in creating a diverse product range.

These cosmetic third party manufacturing companies in India are known for producing exceptional products across various segments, including Skin care products, Hair care products, Baby care products, Ayurvedic products, Herbal products, Dermatological products, Beauty care products and Oral care products like Toothpaste & Mouthwash.

A cosmetic third party manufacturing company offers comprehensive cosmetic manufacturing services, ensuring that all products are manufactured to the highest standards. These companies provide private label manufacturing services, enabling brands to develop private label lines that meet specific market needs. The flexibility of third-party manufacturing allows brands to scale their operations and introduce new cosmetic lines without the need for significant capital investment in their own manufacturing units.

Leading private label cosmetic manufacturers and third party manufacturers in India focus on producing best quality products that protect the skin from environmental factors while catering to consumer demands for natural and organic ingredients. These manufacturers take care of everything from formulation to packaging of products according to client specifications, ensuring a seamless process from concept to market.

Private label and third party manufacturers offer the best solutions for brands looking to expand their range of skin care, hair care, and body care products. By utilizing third party contract manufacturing, brands can offer high-quality beauty care products and grooming products under their own labels, enhancing their market presence and meeting consumer expectations.

Summary

Partnering with a third party cosmetic manufacturing company in India allows brands to leverage core innovations for manufacturing and deliver best quality cosmetic products. These partnerships with cosmetics manufacturing companies are essential for producing a wide range of cosmetic products, from high-quality skin care to beauty care solutions, ensuring that brands can sell the products that meet their customers needs. Through these collaborations, brands can achieve their goals of offering exceptional products and maintaining their reputation among the top in the industry.